Specifications for Lead Screw Assemblies

All lead screws are shipped fully assembled and "run in" to intimately mate the screw and nut.

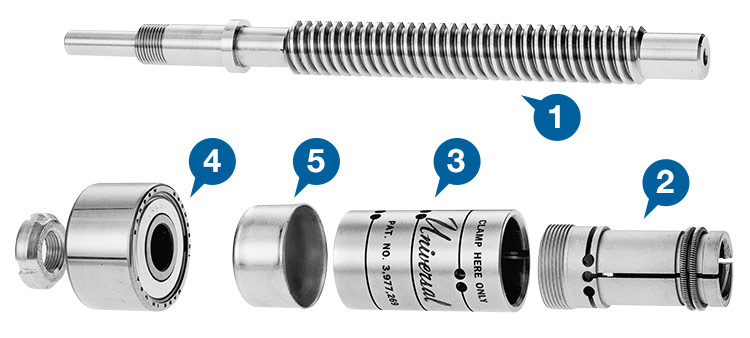

1. Precision Lead Screw

Manufactured of hardened, low temperature stabilized A6 tool steel, in four accuracy grades. Threads are ground and lapped. Thread to thread error as low as 0.000010" including drunkenness. Each screw is "run in" with its own nut.

2. Preloaded Nut

One piece phosphor bronze split nut is self-adjusting. Radially preloaded nut halves respond to the average lead, further reducing residual one turn screw errors. Improved design achieves increased axial stiffness and suppresses backlash.

3. Self-aligning Thrust Bushing

Multiflexured, one piece bushing transfers thrust from the nut to the external load in a theoretically ideal way. Reduces effects of residual eccentricity of lead screw and errors due to slide nonlinearity. Minimizes loading of air bearing slides.

4. Thrust Bearing

Precision preloaded double row ball thrust bearing, in a selection of axial thrust accuracies as good as 0.000010". Thrust bearing error adds directly to the lead screw drunkenness error. Lead screw performance is compromised unless a bearing with equally small errors is selected and properly fitted. We select the best available, epoxy them in place, and retest after fitting. We can also advise you on practical techniques to achieve extreme thrust accuracies better than 0.000005".

5. Optional Lubricator

The optional lubricator, factory installed on the nut, removes dust and lubricates the screw in applications where the screw is exposed and continuous lubrication cannot be provided. Periodic reoiling of the lubricator is required; we can supply the recommended oil.

Specifications

Lead screw material – A6 hardened and low temperature stabilized.

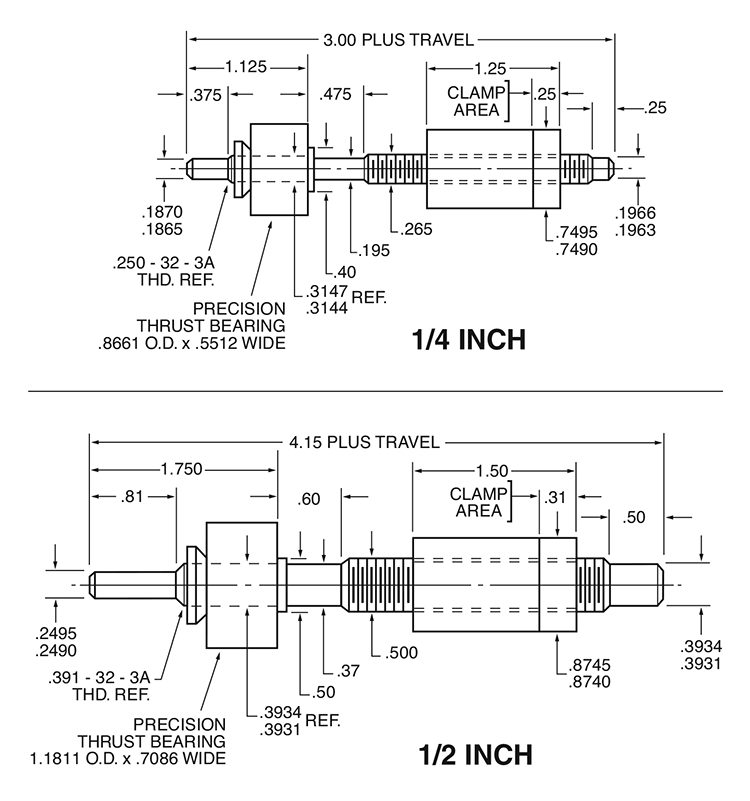

| Lead Screw Diameter | 1/4" | 1/2" |

|---|---|---|

| Maximum Available Travel | 8" | 20" |

| Standard Leads* | .025", .050", .100", .200", 1 mm, 2 mm | .025", .040", .050", .100", .125", .200", .400", 1 mm, 1.25 mm, 2 mm, 2.5 mm, 5 mm |

| Maximum No-Load Torque | 4 oz in | 8 oz in |

| Maximum Load (Including Inertial) | 30 lb | 50 lb |

| Working Load (Including Inertial) | 8 lb | 10 lb |

| Stiffness of Nut | 4 lb / .0001" | 5 lb / .0001" |

Lead Accuracy Specification

| "X" | "XX" | "XXX" | "XXXX" |

|---|---|---|---|

| .000050"/ turn | .000025"/ turn | .000010"/ turn | .000010"/ turn |

| .000100"/ inch | .000050"/ inch | .000025"/ inch | .000025"/ inch |

| .0004"/ foot | .0002"/ foot | .0002"/ foot | .0001"/ foot |

Bearing Thrust Plane Accuracy

| Standard | .000030" |

|---|---|

| Available | .000015", .000010" |

We will be glad to review your application and help you specify the lowest cost unit that will meet your requirements. We can advise you on special techniques to increase axial stiffness, and to achieve thrust plane accuracies better than 0.000005".

Notes:

- Nut can be factory assembled facing either direction, with clamp area closest to thrust bearing or away from thrust bearing. NUT ASSEMBLY MUST NOT BE REMOVED. Specify desired orientation when ordering.

- Optional lubricator is installed on end of nut opposite clamp area. Must be factory installed when lubricator end of nut faces thrust bearing. Adds .38" to length of 1/2" nut, which may reduce travel and/or restrict installation options in some cases. Not available for 1/4" assemblies.